Terrantic seals $3.5m to help food processors extend shelf life and increase production yields

Leading the round was Supply Change Capital, the investment firm in early-stage food and agriculture technology companies backed by General Mills.

There was also participation from York IE and Vitalize VC as well as existing investors Array Ventures.

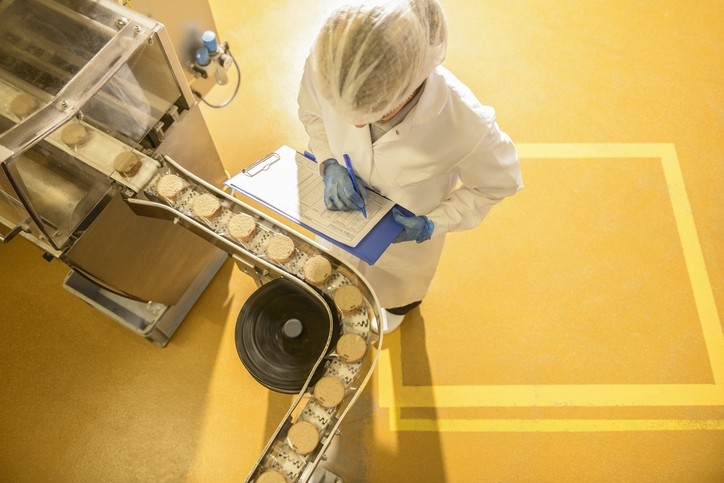

Seattle-based Terrantic offers a platform that integrates disparate data sources from food growers, processors, and packhouses. This platform then applies sophisticated algorithms and AI to generate actionable insights from the consolidated data.

The company specifically targets food growers, food processors and packhouses. Its main goal is to help food producers become more efficient by optimising throughput and yield, reducing downtime and labour costs and minimizing waste due to scrap, rejects, and shrinkage.

Informing better data-driven decisions

Terrantic's platform enables food producers to make better data-driven decisions, adapt more effectively to external events, and unlock improvement opportunities using their existing data. The founders of Terrantic have experience in developing data-based decision-making software for the mining industry. They are now applying this expertise to the food production sector.

Their broader vision is to significantly reduce food waste in the US. By providing these data-driven solutions, Terrantic aims to address the major challenges facing food producers today, including labour problems, supply chain issues, rising competitiveness, and squeezed margins.

Minimising food waste and improving yield

The US generates around 77.6 million tonnes of food waste annually across all sectors. This amount of food waste represents about 30-40% of the total food supply in the US.

Terrantic will invest the capital to continue helping food processing companies minimise food waste and improve yield by optimising their supply chain operations and ensuring their products reach their destination at their best quality.

"An optimized and data-informed supply chain is critical to enabling a sustainable food system. Operational efficiency and data insights within the supply chain - from food processing to agriculture to process manufacturing - are the keys," said Noramay Cadena, managing partner, Supply Change Capital. " Terrantic’s technology will modernize operations for the industry and improve food system sustainability."

Food waste is a major issue for food manufacturers, causing significant loss of time and money. Advances in data collection and the advent of matching learning models, however, have created a meaningful opportunity for the largely manual fresh food industry and their downstream partners. By connecting disparate data sources and providing context across siloed operations and organizations, Terrantic’s aim is to efficiently learn an organization's operations, optimize planning and scheduling and enable peak operational efficiency.

"Our goal is for food processing companies to never have to review a business intelligence report or pay for data professional services again," said Trevor Cox, co-founder and chief business officer, Terrantic. "We are proud to be at the forefront of this emerging market and look forward to using this funding to help more food processing companies become more productive."

A $20 billion opportunity?

Columbia Fruit, Servico, the University of California Merced and others currently use on Terrantic's AI-driven contextualization engine to solve for operative disruptions in food processing, increase shelf life and improve margins and throughput. In the US alone, there is a $20 billion serviceable market for growers and food processors, according to the company.

"Our technology is the nerve center that provides food processors with the end-to-end visibility and contextual execution they need to connect the food supply chain," said Krishna Srinivasan, co-founder and CEO, Terrantic. "Our technology is the foundational operating system that has helped food processing companies increase shelf life by 20% and production throughput by 40%, and we are just getting started. Investments in improving our technology and sales engine will help us reach and change the operations of many more companies in the future."